|

How does XRF work?

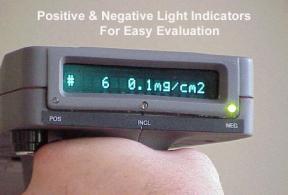

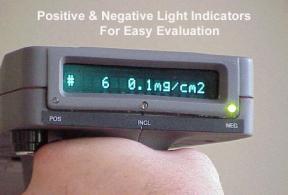

- The surface to be measured

is irradiated with gamma rays that excite the emission of K shell x-rays.

The gamma ray source in the LPA-1 XRF is an isotope of cobalt, Co57.

The x-rays are then collected by a solid state radiation detector within

the analyzer. The lead concentration is then computed and displayed

in mg/cm2.

- The LPA-1 method of measurement

is based on the spectrometric analysis of lead K-shell x-ray fluorescence

in a controlled depth of paint. K-shell energy can easily go through

the paint without being affected by different thickness and composition

of various layers of paint that can cause false readings. Controlled

depth used in the design of the LPA-1 XRF Lead Paint Analyzer restricts

the penetration of the energetic K-shell x-rays into the substrate.

The system cannot be misled by the presence of lead pipes or other objects

located deep in a wall.

What makes the LPA-1

so fast?

|

|

- In designing the instruments,

RMD, now PROTEC Instrument Corporation, worked with government agencies

and the inspection community to understand the issues facing the lead

paint inspector. Productivity and portability consistently came

back as themes in almost all of the discussions. Utilizing their

extensive knowledge in microprocessor based analytical instrumentation,

the engineers designed an intelligent instrument that acquires and analyzes

data simultaneously. In addition, the LPA-1 are true spectrum

analyzers. While some instruments require the user to visually

evaluate a spectrum and interpret results, the LPA-1 are intelligent

enough to acquire a spectrum, interpret it, and compute a result without

help from the user. They perform this process faster and more

accurately then can possibly be done by the human eye giving it astounding

speed of measurement.

|

How long is the half

life for CO57 and when do I resource the instrument?

- The half life for CO57 is

approximately nine months (272 days). The source will decay at

the same rate whether the instrument is used once or a million times.

It is not necessary, however, to change the source after one half life.

The source in the LPA-1 can be used well beyond nine months. In

fact the instrument’s intelligence will automatically adjust for the

age of the source in Quick Mode or when using the Time Corrected Mode

during calibration checks. The recommended source change is 15-18

months.

How much radiation is an

operator exposed to by the LPA-1?

- The LPA-1 Analyzer contains

a maximum of 12 mCi (millicurie) of Cobalt 57 (Co57) radioactive material

sealed, and housed in a tungsten shield inside the instrument.

The source can only be exposed when the system is in contact with a

surface. The low activity of the source and the shield, along

with proper operation results in no radiation hazard to the operator.

The radiation dose rate at the operators hand is approximately 0.3 mRem/hr

(Millirem per hour) with the shutter open or closed. This is substantially

below the permissible dose rate. The LPA-1 Analyzer has been through

the Device Safety Evaluation Review and is a nationally registered device.

Has the LPA-1 been issued

a Product Characteristic Sheet (PCS)?

- The LPA-1 has been issued

a Performance Characteristic Sheet (PCS). Call us to obtain a

copy. It is also available for downloading from our website, the HUD

website or by calling the HUD clearing house at 1-800-424-LEAD.

What is required before

PROTEC Instruments can deliver my LPA-1?

- In order to deliver any LPA-1

three items must be completed.

1. The user must receive a license or registration from the local

state agency. Some states accept a general license. (Call for the LPA-1

Specification & Licensing Requirements for instructions).

A copy of the device specific license or general license registration

approval may be mailed or faxed to PROTEC Instruments prior to shipment.

2. The user must complete a factory authorized training course.

The training, which is provided by an authorized representative of PROTEC

Instruments, can be completed in one day and is included in the purchase

price.

3. Payment must be arranged and confirmed. Accepted methods

include, a certified or bank check, a signed and approved lease agreement,

or an institution or government purchase order.

Do I have to go to Watertown

Massachusetts to be trained?

- While customers are always

welcome to train and tour the facility in Watertown, MA, PROTEC Instruments

holds regular training sessions around the country. Contact us

for exact location and dates. Safety training is also available

on line. Contacy us for details.

Can I finance the LPA-1

instrument? If so, how?

- For those who wish to finance

their purchase, PROTEC Instruments works through several leasing companies

to allow customers to spread out payment in convenient monthly installments.

Contact PROTEC Instruments for a list of lease-to-own companies.

Will the software run on my computer?

- The software is compatible

with all Windows® operating systems

|

|

What is included

in the LPA-1 Lead Paint Spectrum Analyzer Package?

|

|

- (1) XRF Analyzer

- (2) Rechargeable batteries

- Battery Charger

- (2) stabilizers

- Standard reference material

for calibration

- Instruction manual

- Computer interface cable

- Windows® based software

- Software instruction

manual

- Foam-lined carrying

case

- Optional portable hand

held PC

- Warranty: parts &

labor – 2 years

|

|

How long has RMD

/ PROTEC Instruments been in the instrumentation business?

|

|

RMD Instruments, now PROTEC

Instrument Corporation, has been producing quality nuclear instrumentation

since 1974, and is one of a few companies in the world with the technology

to produce Cadmium Telluride (CdTe) for commercial use, a critical

component in the detection of X-rays in the LPA-1 Analyzer.

Some of the other products include nationally recognized surgical

probes for radiological medicine and imaging, safety monitors for

nuclear power plants, systems for nuclear surveys, and quality control

instruments for analyzing composite and plastic materials. PROTEC

Instrument Corporation has always been committed to providing total

support to their customers through innovative products and services |

|